News

- Why multi-point automatic welding machine is more efficiency?Youngmax multi-point automatic weld machine, is more efficiency than single point welding machine. Saving more time means you can increase the product capacity during the production. Youngmax multi-point automatic weld machine, is more efficiency than single point welding machine. Saving more time means you can increase the product capacity during the production. The multi-point automatic weld machine has many advantage: easy to operate, low investment and quick return. 1. Capacity: 430-450 pcs / hour(for reference only) 2. Low technical requirements for workers, save labor cost 3. Multi-point welding at the same time, high efficient 4. Parameters of each point can be adjusted separately depend on different factory's capacity 5. Welding point strength stressed 6. Constant conduction angle control, good in welding current We sell the multi-point automatic weld machine to many countries like India, Bangladesh, Iran, Turkey, etc We provide the comprehensive after-sale service for our every client. Youngmax machine focus on providing A-Z solution of household appliance production!

2023 11/10

- Cutting-Edge Technology: New Edge Trimming Machine Revolutionizes ManufacturingInnovative Equipment Promises Efficiency and Precision in Edge Trimming Processes The new edge trimming machine, developed by Foshan Youngmax Machine Co., Ltd, is set to disrupt traditional manufacturing methods across a range of sectors, from automotive and aerospace to consumer electronics and packaging. This innovation comes at a time when industries are constantly seeking ways to enhance productivity, reduce waste, and meet increasingly stringent quality standards. Key Features and Benefits: Precision and Consistency: The edge trimming machine employs advanced computer vision and artificial intelligence algorithms to ensure precise and consistent trimming, regardless of the material or product being processed. This eliminates human error and enhances product quality. Efficiency: With rapid processing capabilities, this machine can significantly reduce production time, leading to increased output and cost savings for manufacturers. Versatility: It can handle a wide variety of materials, from metals and plastics to composites and textiles, making it adaptable for use in diverse industries. User-Friendly Interface: The machine features an intuitive user interface that allows operators to easily program and adjust trimming parameters, reducing the learning curve for employees. Safety: Built-in safety features and sensors ensure a secure working environment, minimizing the risk of accidents and injuries. Industry Experts Praise the Innovation: Leading experts in manufacturing technology have lauded the new edge trimming machine. Dr. David, a renowned industry analyst, stated, "This technology represents a significant leap forward in manufacturing efficiency and precision. It has the potential to transform entire industries, setting new standards for quality and productivity." Global Impact: The impact of this innovation is expected to resonate globally, as companies across the world seek to modernize their manufacturing processes. This edge trimming machine has already gained interest from international manufacturers looking to streamline their operations and gain a competitive edge in the market. Environmental Benefits: In addition to its economic advantages, the new edge trimming machine has the potential to reduce waste in manufacturing processes, aligning with sustainability goals and environmental responsibilities. Final Thoughts: With its groundbreaking technology and impressive range of capabilities, the new edge trimming machine promises to be a game-changer for manufacturing industries. As more companies embrace this cutting-edge solution, it is anticipated that manufacturing processes will become not only more efficient but also more sustainable. For more information on this innovative edge trimming machine and its applications, please visit our website: www.ymaxmachine.com

2023 09/20

- Revolutionary Annealing Machine Promises Breakthroughs in Material Science and ManufacturingCutting-edge technology poised to transform industries with unprecedented precision and efficiency. In a significant leap forward for material science and manufacturing, a groundbreaking annealing machine is set to redefine the landscape of industrial processes. The new machine, developed by a team of leading scientists and engineers, promises to bring unparalleled precision and efficiency to the annealing process, unlocking vast possibilities for a range of industries. The Annealing Revolution Annealing, a heat treatment process, plays a pivotal role in enhancing the properties of materials such as metals, glass, and semiconductors. Traditionally, this process involved heating and cooling materials at precise temperatures to alter their physical and chemical characteristics. However, the newly developed annealing machine introduces a transformative approach that pushes the boundaries of what's possible. Unprecedented Precision and Efficiency The innovative annealing machine employs cutting-edge technologies, including advanced sensors, artificial intelligence algorithms, and precise temperature control mechanisms. This amalgamation of technology ensures that materials undergo annealing with a level of precision previously thought unattainable. Key Advancements: Ultra-Fast Processing: The machine boasts an exceptional processing speed, drastically reducing production times. This not only enhances productivity but also reduces energy consumption. Customizable Annealing: The AI-driven interface allows users to tailor the annealing process to specific materials and desired outcomes with remarkable accuracy. Energy Efficiency: By optimizing the heating and cooling cycles, the machine significantly reduces energy consumption, making it an environmentally friendly solution. Wide-Ranging Applications The potential applications of this breakthrough annealing machine are vast and varied: Aerospace: Aerospace manufacturers can benefit from stronger, lighter, and more durable materials, improving aircraft performance and fuel efficiency. Electronics: Semiconductor manufacturers can produce smaller and more powerful microchips, pushing the boundaries of technology. Medical Devices: Medical equipment and implant manufacturers can create safer and more biocompatible materials for critical applications. Automotive: Automakers can produce vehicles with enhanced structural integrity and reduced weight, leading to improved fuel efficiency and safety. Energy Sector: Renewable energy technologies, such as solar panels and wind turbines, can see increased efficiency and longevity. Global Impact The introduction of this advanced annealing machine has the potential to revolutionize multiple industries globally, driving innovation, reducing waste, and increasing product quality. Furthermore, the machine's energy-efficient design aligns with sustainability goals, offering a responsible path forward for industrial manufacturing. A Glimpse into the Future As industries continue to evolve, technological innovations like this revolutionary annealing machine are poised to drive progress and redefine what is possible. With unprecedented precision, efficiency, and a commitment to sustainability, this machine promises to be a cornerstone of future advancements in material science and manufacturing. Conclusion The unveiling of this pioneering annealing machine marks a significant milestone in the world of material science and manufacturing. As industries adopt this transformative technology, we can anticipate a future where materials are stronger, more efficient, and more environmentally friendly than ever before, opening up new horizons for innovation across the board.

2023 09/15

- High efficient and cost saving customized trimming machineA non-stick pan is a type of cookware that has a coating applied to its surface, which prevents food from sticking to it during cooking. This coating is typically made of polytetrafluoroethylene (PTFE), commonly known as Teflon. In Asia, non-stick pans have gained popularity due to their convenience and ease of use. They are commonly used for various cooking methods like frying, sautéing, and stir-frying. The non-stick feature allows for easy food release and makes cleaning the pan a breeze. The marketing situation of non-stick pans in Asia is quite competitive. Many international and local brands offer a wide range of non-stick cookware options to cater to the diverse preferences and cooking styles in the region. These pans are available in various sizes, shapes, and price ranges to suit different consumer needs. During the production of the non-stick pans, trimming machine is very important. Our updated trimming machine is has cutting and beading function, can reduce machine coast and increase the capacity. Youngmax machine focus on providing A-Z solution of household appliance production, our main product range include: Metal Stamping Machinery Drawing and Forming Machinery Polishing Machinery Surface Treatment Production Line Other Auxiliary Machinery Automatic Manipulator Mould

2023 08/29

- What does multi stations crimping machine can do?A crimping machine is a mechanical device used to create a secure and reliable electrical or mechanical connection between two or more components. It is commonly used to attach a connector or terminal to the end of a wire or cable. The process of crimping involves deforming a metal component (such as a terminal or connector) around a wire, creating a strong and durable connection. Crimping machines are widely used in various industries, including: Electronics: Crimping machines are used to create reliable connections in the assembly of electronic components, cables, and wire harnesses. Automotive: Crimping machines are used in the automotive industry to create connections for electrical systems, sensors, and wiring harnesses. Aerospace: Aerospace applications use crimping machines to ensure secure connections for avionics systems and wiring. Telecommunications: Crimping machines are used to create connections for telephone cables, network cables, and fiber optics. Industrial Equipment: Crimping machines are used in the manufacturing of industrial machinery and equipment that require precise and reliable electrical connections. Appliances: Household appliances often require crimped connections for various electrical components. Crimping machines can come in various types, including handheld tools for manual crimping, pneumatic machines that use air pressure for crimping, and hydraulic machines that use hydraulic pressure for more heavy-duty applications. The crimping process typically involves placing the wire or cable into a terminal or connector, positioning it in the crimping machine, and then applying pressure to deform the metal component around the wire, creating a secure connection. Overall, crimping machines play a crucial role in ensuring the integrity and reliability of electrical and mechanical connections in various industries. We, Youngmax machine are A-Z solution provider of home appliance production Except for the crimping machine, we still provide: Metal Stamping Machinery Drawing and Forming Machinery Polishing Machinery Surface Treatment Production Line Other Auxiliary Machinery Automatic Manipulator Mould

2023 08/09

- How to make deluxe rice cooker?To make rice in a rice cooker, follow these steps: 1. Measure the desired amount of rice using the measuring cup that comes with the rice cooker. Typically, 1 cup of uncooked rice makes about 2 cups of cooked rice. 2. Rinse the rice under cold water until the water runs clear. This helps remove excess starch and improves the texture of the cooked rice. 3. Place the rinsed rice in the rice cooker inner pot. 4. Add the appropriate amount of water according to the rice cooker's instructions. The ratio of water to rice varies depending on the type of rice being used. Generally, for white rice, the ratio is 1:1, meaning 1 cup of rice requires 1 cup of water. For brown rice, the ratio is usually 1:1.5 or 1:2, with 1 cup of rice requiring 1.5 to 2 cups of water. 5. Close the rice cooker lid and press the "Cook" or "Start" button. The rice cooker will automatically start cooking the rice. 6. Once the rice is cooked, the rice cooker will switch to the "Keep Warm" mode to keep the rice warm until you are ready to serve. 7. Let the rice sit in the rice cooker for a few minutes before fluffing it with a fork or rice paddle. This helps the rice settle and become fluffy. 8. Serve the cooked rice immediately or keep it warm in the rice cooker until ready to serve. Additionally, if you have factory or own workshop and want to invest in rice cooker production. We can provide you the whole solution proposal. Basic machine for rice cooker making: Hydraulic press machine Hardware/plastic mold Metal polishing machine Trimming machine Punching machine

2023 08/04

- How to Use a Screen Printing Machine for Optimal ResultsScreen printing has been widely adopted in various industries, ranging from apparel and textiles to packaging and signage. To achieve the best results, it is essential to understand the proper usage of a screen printing machine. Here are some key steps to effectively use a screen printing equipment: Prepare the Equipment: Ensure that you have all the necessary equipment, including a best screen printing machine, screens, squeegees, ink, and substrates. Set up your workspace in a clean and well-ventilated area. Preparing the Design: Create or acquire the design you want to print. Digital designs can be converted into stencils using photo emulsion technique, while manual designs can be made using films or hand-cut stencils. Setup the Machine: Install the screens onto the machine, ensuring that they are securely tightened. Adjust the screen tension and position it properly for accurate printing. Set up the ink and squeegee on the designated stations. Ink Preparation: Choose the appropriate ink for your substrate and mix it thoroughly. Adjust the ink consistency if needed. Test the ink on a sample material to ensure the desired print quality. Printing Process: Place the substrate onto the printing platen, ensuring it is aligned properly. Lower the screen onto the substrate and apply the ink on the screen using the squeegee, moving it smoothly and evenly across the screen. Lift the screen to reveal the printed design. Repeat this process for each substrate. Drying and Curing: After printing, carefully remove the substrate from the printing platen and place it in a designated drying area. Allow the ink to dry naturally or use a curing unit to accelerate the drying and curing process. Clean and Maintain: After completing your printing job, clean the screens, squeegees, and other equipment properly to prevent ink residue build-up. Regularly inspect and maintain your screen printing machine to ensure optimal performance and longevity. By following these steps, you can maximize the efficiency and quality of your screen printing process. As technology advances, automatic screen printing machine has become more popular due to its increased speed and accuracy. Investing in the best screen printing machine suitable for your specific needs can further enhance productivity and ensure professional results in your industry.

2023 07/05

- How to Find the Perfect Automatic Manipulator Shut-off Valve?In today's rapidly evolving industrial landscape, automated systems and robotics are becoming increasingly prevalent. Among these technologies, stretching and unloading manipulator, such as six-axis robot and three-axis manipulator, play a vital role in increasing productivity and efficiency. A crucial element in the operation of these manipulators is the automatic shut-off valve. Here are some key tips on finding the perfect shut-off valve for your automatic manipulator system. Understand Your System Requirements: Before searching for a shut-off valve, it is essential to have a clear understanding of your manipulator system's specific requirements. Consider factors such as the operating pressure, temperature range, and flow rate. These factors will help you determine the type and specifications of the shut-off valve needed. Research and Compare Different Valve Types: There are various types of shut-off valves available, including ball valves, gate valves, butterfly valves, and globe valves. Each valve type has its own advantages and disadvantages. Research and compare the characteristics and features of different valves to determine which type is best suited for your manipulator system. Consider Valve Material and Construction: The material and construction of the shut-off valve are crucial factors that impact its performance and longevity. Depending on the operating conditions of your manipulator system, consider materials such as stainless steel, brass, or plastic. Additionally, evaluate the valve's construction to ensure it can handle the pressure, temperature, and any potential corrosive or abrasive substances present in your application. Seek Expert Advice and Supplier Support: Consult with industry experts and experienced suppliers to get their insights and recommendations. They can provide valuable guidance on valve selection based on your specific requirements. Additionally, they can offer technical support and assistance during the installation and maintenance of the shut-off valve. Finding the perfect automatic manipulator shut-off valve is vital to ensure the smooth and efficient operation of your system. By understanding your system requirements, researching different valve types, considering materials and construction, and seeking expert advice, you can make an informed decision. Investing in a high-quality shut-off valve will enhance the reliability, safety, and performance of your stretching and unloading manipulator system, contributing to increased productivity and overall success in your industry.

2023 07/04

- The Impact of Mold Material on Product Quality and EfficiencyThe material of the mold plays a critical role in the manufacturing process, determining the final quality and efficiency of the produced goods. Different mold materials have varying characteristics and properties that can significantly influence the outcome of the production process. Let's delve into the impact of mold materials such as aluminum die casting mold, Bakelite mold, and plastic injection mold on various industries. Aluminum Die Casting Mold: Aluminum die casting molds are widely used in industries such as automotive, aerospace, and home appliances. The use of aluminum molds offers several advantages, including excellent thermal conductivity, high rigidity, and superior dimensional stability. These properties contribute to the production of high-precision components with intricate designs, ensuring the durability and performance of the finished products. Bakelite Mould: Bakelite molds are extensively employed in the electrical and electronics industry. Bakelite, a type of thermosetting plastic, offers excellent electrical insulation properties, heat resistance, and dimensional stability. These characteristics make Bakelite molds suitable for producing electrical switches, outlets, connectors, and other high-temperature resistant components. Plastic Injection Mold: Plastic injection molds are utilized in a wide range of industries, including automotive, consumer goods, and medical devices. The choice of mold material for plastic injection molds depends on factors such as the type of plastic being processed, the desired product finish, and the expected production volume. Common mold materials for plastic injection molding include steel and aluminum alloys, which offer excellent durability, reliability, and resistance to wear and tear. The selection of the appropriate mold material is crucial in achieving consistent product quality, reducing production time, and maximizing operational efficiency. Manufacturers must consider factors such as the product requirements, production volume, and cost-effectiveness when deciding on the mold material. By understanding the relationship between the mold material and its impact on the manufacturing process, industries can optimize their production systems and deliver superior quality products to meet the ever-growing market demand.

2023 07/02

- What kitchen utensils can the Welding Machine make?In the manufacturing industry, welding machines play a crucial role in creating various products, including kitchen utensils. The versatility and precision of different welding techniques have revolutionized the production process, allowing for the creation of high-quality kitchen tools. Let's explore some common kitchen utensils that can be made with different welding techniques. Spot Welding: Spot welding is a popular technique used to join two or more metal sheets together. This method is extensively used in the production of cookware handles, such as frying pans, saucepans, and pots. The spot welding process ensures a strong and durable bond between the handle and the body of the utensil. Brazing Machine: Brazing is another welding method commonly applied in the manufacturing of kitchen utensils. With the help of a brazing machine, metal pieces like stainless steel or copper can be joined together, creating items like stainless steel colanders, strainers, and tea infusers. These utensils require a strong and leak-proof connection, which brazing effectively achieves. Stud Welding: Stud welding is widely used to attach studs or bolts to metal surfaces, making it ideal for creating kitchen utensils like wall-mounted pot racks and kitchen towel holders. Stud welding provides a secure mounting option that can withstand the weight of pots and pans, improving kitchen organization and efficiency. Straight Seam Welding Machine: Straight seam welding machines are commonly used in the production of kitchen sinks. These machines ensure precise and uniform welding along the seams, resulting in seamless and leak-free sink units. The straight seam welding technique is essential for creating stainless steel sinks, which are known for their durability and easy maintenance. In the kitchen utensil manufacturing industry, welding machines, including spot welding, brazing machines, stud welding, and straight seam welding machines, enable the production of a wide range of products. These machines ensure the strength, durability, and functionality of kitchen tools, meeting the needs and expectations of consumers worldwide.

2023 07/01

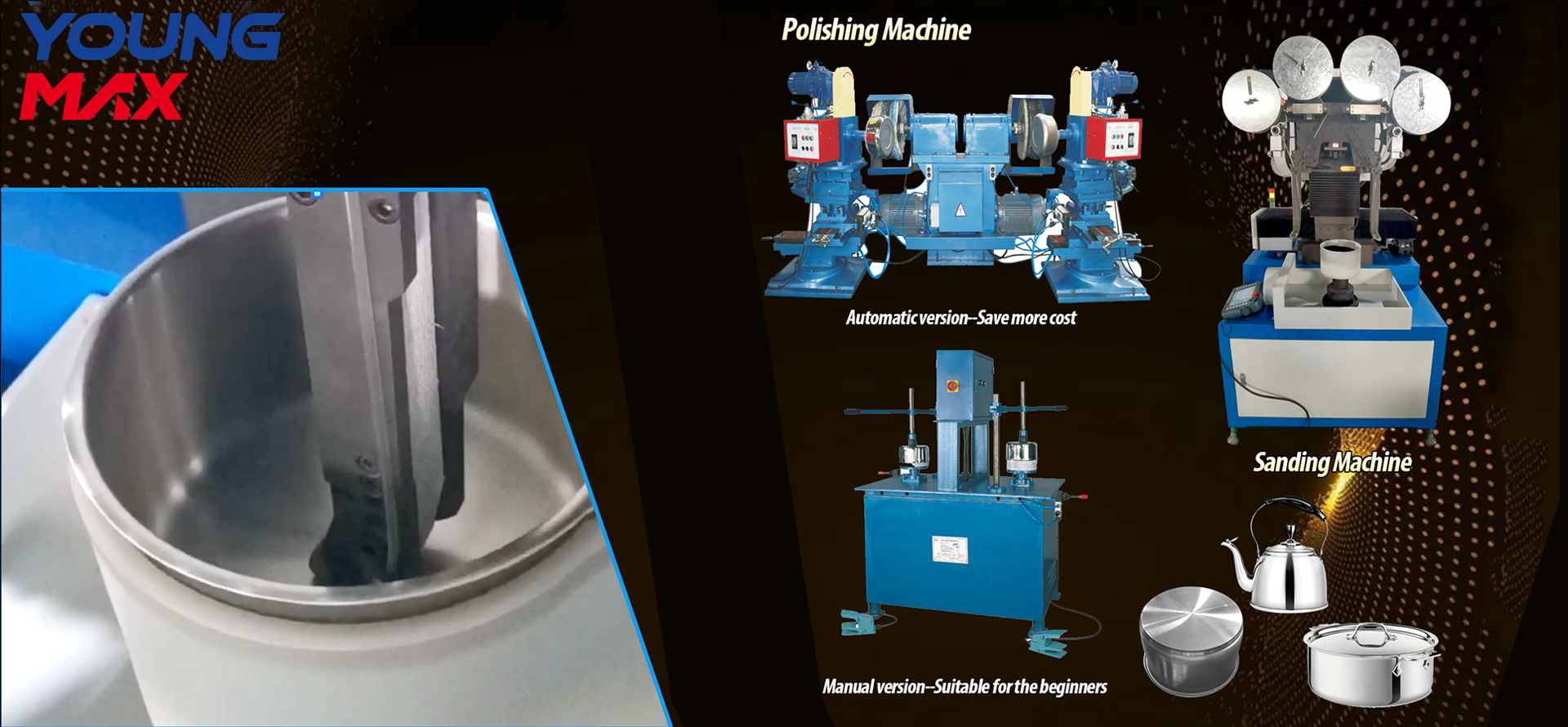

- What is the sanding polishing machineSanding polishing machine is a power tool that is used to remove imperfections and smooth surfaces. Sander polishing machine typically consists of a motorized device with a rotating abrasive pad or wheel that is used to sand or polish various materials such as wood, metal, or plastic. Sanding polishing machines are versatile tools that can be used in various applications. Some common applications include: 1. Woodworking: Sanding and polishing machines are commonly used in woodworking to smooth and finish wooden surfaces. They can be used to remove imperfections, such as scratches and blemishes, and create a smooth and polished finish on furniture, cabinets, doors, and other wooden objects. 2. Metalworking: These machines are also used in metalworking to remove rust, paint, and other coatings from metal surfaces. They can be used to prepare metal surfaces for painting, welding, or other finishing processes. 3. Automotive industry: Sanding and polishing machines are widely used in the automotive industry for various applications. They can be used to remove scratches and swirl marks from car body panels, polish headlights, and restore the shine and luster of automotive paint. 4. Construction and renovation: These machines are often used in construction and renovation projects to prepare surfaces for painting or refinishing. They can be used to remove old paint, varnish, or other coatings from walls, floors, and other surfaces. 5. DIY and home improvement: Sanding and polishing machines are popular tools for DIY enthusiasts and homeowners. They can be used for a wide range of projects, such as refinishing furniture, restoring wooden floors, polishing countertops, and even sanding drywall. Overall, sanding and polishing machines have a wide range of applications in various industries and can be used to achieve smooth, polished, and finished surfaces on different materials. The metal polishing machine can be used for tasks such as removing paint or varnish, smoothing rough edges, or creating a polished finish on surfaces. Inner and bottom side polishing machine can be used in cookware, rice cooker, pressure cooker, and many kinds of metal products.

2023 07/03

- How to make high quality stainless steel cookware?How to make high quality stainless steel cookware? Stainless steel cookware is available in various types and configurations to suit different cooking needs. Here are some common types of stainless steel cookware: Stainless Steel Pots and Pans: These are the most basic and versatile types of stainless steel cookware. They come in various sizes and are suitable for a wide range of cooking tasks, such as boiling, simmering, frying, and sautéing. Stainless Steel Saucepan: A saucepan is a smaller-sized pot with high sides and a long handle. It is ideal for making sauces, reheating leftovers, boiling small quantities of liquids, and cooking grains. Stainless Steel Stockpot: A stockpot is a large, deep pot with straight sides and a lid. It is designed for preparing stocks, soups, stews, and boiling large quantities of liquid. Stainless Steel Dutch Oven: A Dutch oven is a heavy and deep pot with thick walls and a tight-fitting lid. It is excellent for slow cooking, braising, and making one-pot meals. Stainless Steel Sauté Pan: A sauté pan has straight sides, a large surface area, and a long handle. It is used for sautéing, searing, frying, and browning ingredients. Stainless Steel Skillet/Frying Pan: Skillets or frying pans are shallow, wide-bottomed pans with sloping sides and a long handle. They are perfect for frying, browning, and shallow cooking tasks. Stainless Steel Grill Pan: Grill pans have raised ridges or grill marks on the cooking surface, which allows for healthier cooking by reducing the contact between food and fats. They are used for grilling indoors, giving food a grilled appearance and flavor. Stainless Steel Roasting Pan: Roasting pans are rectangular or oval-shaped pans with low sides and a rack. They are designed for roasting meats, poultry, and vegetables in the oven. Stainless Steel Steamer: Steamers consist of a pot or pan with a perforated insert or steaming basket. They are used for steaming vegetables, fish, dumplings, and other delicate foods. Stainless Steel Pressure Cooker: A pressure cooker is a sealed pot that uses high pressure and steam to cook food quickly. Stainless steel pressure cookers are durable, efficient, and offer safety features. Although there are many kinds of different stainless steel cookware, machines are general. It can be divided into hydraulic press machine, sanding polishing machine, robot arm, brazing machine, riveting machine. If you have budget, you can also add powder coating line and ultrasonic cleaning line. Foshan Youngmax machine, focus on providing turn-key solution of home appliance/kitchen utensil/cookware production line, welcome inquiry!

2023 06/29

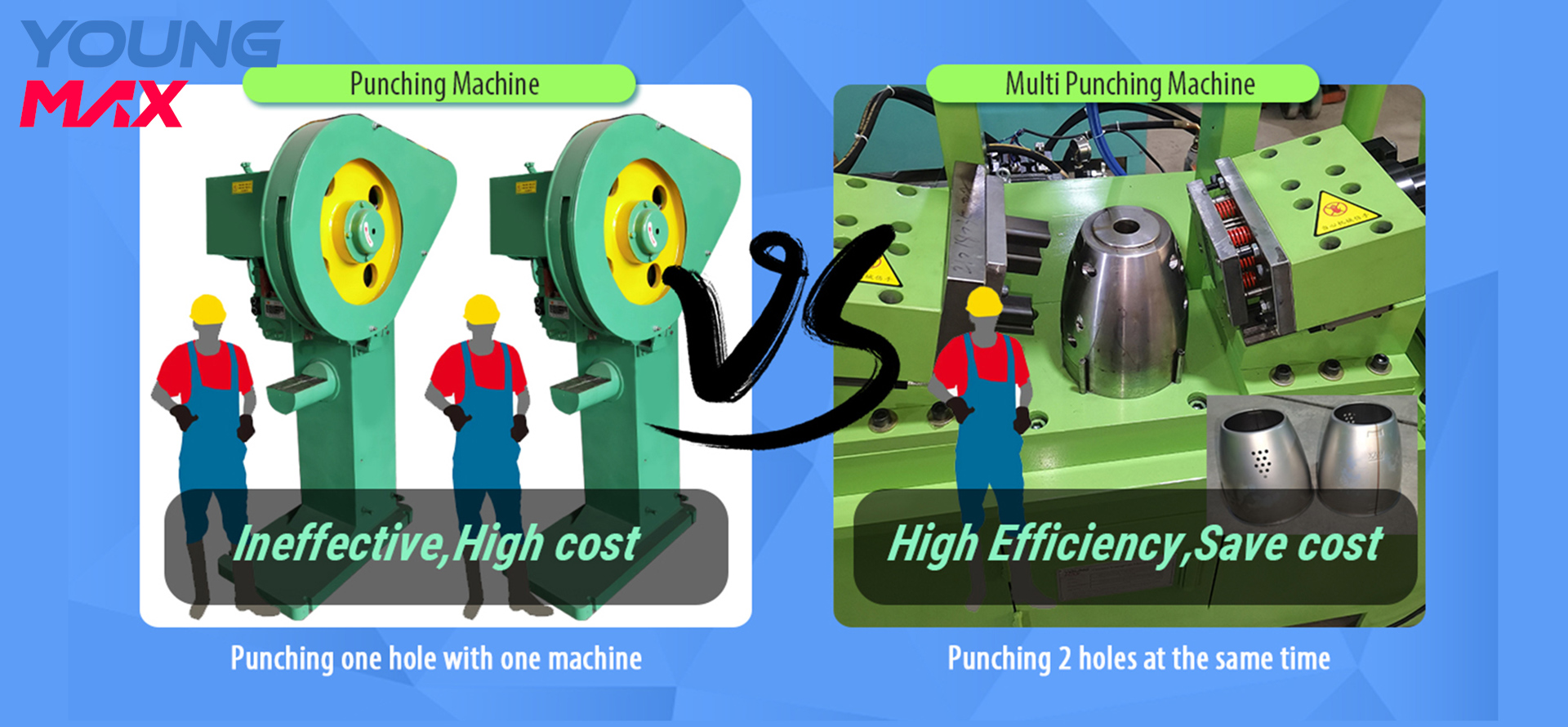

- Only 4 machine can produce cookware!LOL Only 4 machine can produce cookware! Hydraulic pressing machine A hydraulic press machine is a device that uses hydraulic force to exert pressure on a material or object. It utilizes the principles of Pascal's law, which states that when pressure is applied to a fluid, it is transmitted equally in all directions. Hydraulic press machines typically consist of a hydraulic cylinder, a piston, and a press plate. Edge trimming and grooving machine An edge trimming machine is a type of machinery used to trim or cut excess material from the edges of various objects or workpieces. It is commonly employed in manufacturing processes where precise trimming is required to achieve the desired final shape or size. Multi punching machine A punching machine, also known as a punch press or simply a punch, is a machine tool used to punch holes, shapes, or designs in materials such as metal sheets, plastic sheets, paper, and other materials. It applies a force to create a hole or cut out a specific shape by using a punch and a die. Riveting machine A riveting machine, also known as a riveter, is a machine tool used to join or fasten two or more materials together using rivets. Rivets are mechanical fasteners consisting of a cylindrical body with a head on one end and a tail on the other. The riveting process involves deforming the tail end of the rivet to form a second head, creating a permanent joint. For any details, pls contact our team. We have successful case project experience in many countries:)

2023 06/27

- Why we spend so much on cookware cleaning line?A cleaning line typically refers to a range of cleaning products or services offered by a company. It can include a variety of cleaning solutions, detergents, tools, and equipment designed for different cleaning purposes. For example, a cleaning line may include products for household cleaning, industrial cleaning, carpet cleaning, or window cleaning. It can also refer to a specific service offered by a cleaning company, such as a line of services for deep cleaning, regular maintenance cleaning, or specialized cleaning for specific areas like kitchens or bathrooms. Cleaning line can refer to a production line or assembly line designed for cleaning and preparing products or materials. Supersonic cleaning line can also refer to a system of equipment used for cleaning, such as a conveyor belt system that carries products through various cleaning stages. Additionally, metal cleaning line can refer to a designated area or space for cleaning equipment, tools, or other items. Auto cleaning line now is widely used in home appliance field. Many modern factory use it to produce electric kettle outshell, rice cooker outshell, cookware outshell, etc. Automation equipment greatly increase the product capacity, reduce the product defective rate. Cleaning line can have some matching machine such as hydraulic press machine, metal polishing machine, manipulator, trimming machine, punching machine. Youngmax cookware cleaning line can apply to many kinds of cookware, include Stainless Steel Cookware, Non-Stick Cookware, Cast Iron Cookware, Copper Cookware, Ceramic Cookware, Aluminum Cookware, Carbon Steel Cookware, Glass Cookware, Clay Cookware, Titanium Cookware Foshan Youngmax machine is focus on A-Z solution for home appliance production!

2023 06/26

- Why hydraulic pressing brake machine is so important to factory?Hydraulic pressing machine is a type of mechanical equipment that uses hydraulic pressure to compress and shape materials. Hydraulic press brake machine typically consists of a hydraulic cylinder, a piston, and a press frame, which work together to apply force to the material being pressed. Hydraulic pressing machines are commonly used in manufacturing processes such as forging, stamping, and molding, as well as in industries such as automotive, aerospace, and construction. They are known for their high precision, efficiency, and versatility, and can be used to produce a wide range of products with varying shapes, sizes, and materials. Hydraulic press machines are used in a variety of industries for different applications. Some of the common applications of hydraulic press machines are: 1. Metal forming: Hydraulic press machines are used to shape and form metal sheets and plates, like stainless steel, aluminum, etc 2. Die cutting: Hydraulic press machines are used to cut and shape materials such as leather, rubber, and plastic. 3. Powder compaction: Hydraulic press machines are used to compact powdered materials into solid forms. 4. Forging: Hydraulic press machines are used to forge metal parts by applying high pressure and heat. 5. Pressing and stamping: Hydraulic press machines are used to press and stamp materials such as paper, cardboard, and plastics. 6. Sheet metal processing: Hydraulic press machines are used to bend and shape sheet metal for various applications. 7. Assembly: Hydraulic press machines are used to assemble parts and components by pressing them together. 8. Testing: Hydraulic press machines are used to test the strength and durability of materials by subjecting them to high pressure. Foshan Youngmax machine co,.ltd focus on provide turn-key solution for new factory setting up, factory automation upgrading, our factories with more than 10 years manufacturing experience in rice cooker/Kettle/Pressure cooker/Cookware, with our own professional engineering team, we serve from R & D, industrial design, processing, sales till after-sales, our engineers with strong technical strength and on-site practical experience in India/Egypt/Bangladesh/North Africa/Vietnam/Thailand etc. Our main product range from Metal Stamping Machinery, Drawing and Forming Machinery, Polishing Machinery, Surface Treatment Production Line, Other Auxiliary Machinery, Automatic Manipulator, Mould

2023 06/20

- How to produce air fryer?An air fryer is a kitchen appliance that uses hot air to cook food. It circulates hot air around the food, making it crispy on the outside and tender on the inside, similar to deep-frying but without the need for oil. Air fryers are commonly used to cook frozen foods, such as French fries, chicken nuggets, and fish sticks, but can also be used to cook fresh vegetables, meats, and baked goods. They are a healthier alternative to deep-frying because they require little to no oil, reducing the amount of fat and calories in the food. Traditional fryers uses oil to fry food, while an air fryer is a kitchen appliance that uses hot air to fry food. Air fryers are generally considered to be a healthier option as they require little to no oil to cook food, whereas traditional fryers can be high in fat and calories. Air fryers are also typically smaller and easier to clean than traditional fryers. That's why so many people prefer to air fryer in recent years. As home appliance factory, they will import spare parts and then assemble in their factory. To some extent, it can save the customs duty and earn more market shares. If want to make more profits, producing in own factory will be the best choice! Actually, the structure of air fryer is similar with rice cooker. The biggest difference is still the molds. If your factory has already produce rice cooker, there are some machines can be shared with. Firstly, the hydraulic pressing machine. 200ton hydraulic pressing machine is the general machine for deep drawing of the inner pot. Next is the mechanical punching machine. About 110ton is enough. Exact quantity of the machine depends on your daily concrete capacity. Pneumatic punching machine and automatic manipulator works if you have the full budget. Additionally, edge trimming machine is essential. For any details, pls contact us our team. We have successful case project experience in many countries:)

2023 06/19

- How to make various model pressure cooker--Lid part?A pressure cooker is a kitchen appliance used for cooking food quickly by utilizing high-pressure steam. It consists of a sealed pot with a valve that controls the pressure inside. When heat is applied, the liquid inside the pot turns into steam, increasing the pressure and raising the boiling point of the water. This results in faster cooking times and tenderizing tough cuts of meat. Pressure cookers are commonly used for preparing soups, stews, beans, and other dishes that require long cooking times. How to make various model pressure cooker--Lid part? Choose us, we can provide comprehensive service One production line can make various model Cost control & increase market share Easy operation & Low requirements for workers 8618688298083 Youngmax machine focus on providing A-Z solution of household appliance production, our main product range include: Metal Stamping Machinery Drawing and Forming Machinery Polishing Machinery Surface Treatment Production Line Other Auxiliary Machinery Automatic Manipulator Mould

2023 06/16

- Gluing machine for electric kettleGluing machine is a device used to apply adhesive or glue to a surface or material. It can be used in various industries such as printing, packaging, woodworking, and textiles. Gluing machines can range from manual to fully automated and can apply different types of adhesives such as hot melt, cold glue, or pressure-sensitive adhesives. They are designed to improve productivity, accuracy, and consistency in the gluing process. Factory apply the gluing machine mainly in adhering the glass kettle's plastic parts and the glass parts. As we know, nowadays, many customers choose glass kettle, it has many advantage. 1. Visibility: One of the main advantages of a glass kettle is that it allows you to see how much water is inside. This can be helpful when measuring the amount of water needed for different purposes, such as making tea or cooking. 2. Aesthetics: Glass kettles are often considered more visually appealing compared to other materials like stainless steel or plastic. The transparent glass gives a sleek and modern look to the kitchen. 3. Easy to clean: Glass kettles are generally easy to clean because the smooth surface of the glass prevents residue from sticking. This makes it simple to remove any limescale or mineral deposits that may build up over time. 4. No taste transfer: Unlike kettles made from other materials, glass kettles do not transfer any taste or odor to the water. This ensures that your water remains pure and doesn't acquire any unwanted flavors. 5. Safety: Glass kettles are typically made from borosilicate glass, which is known for its high thermal resistance. This means that it can withstand rapid temperature changes without cracking or shattering. Additionally, some glass kettles come with safety features like automatic shut-off and boil-dry protection. 6. Heat retention: Glass kettles are known for their ability to retain heat for longer periods compared to other materials. This can be advantageous if you want to keep your water hot for a longer time, such as when serving multiple cups of tea or coffee. 7. Environmentally friendly: Glass kettles are considered more environmentally friendly than plastic kettles, as glass is a recyclable material. By choosing a glass kettle, you can reduce your plastic waste and contribute to a more sustainable lifestyle. Youngmax machine focus on providing A-Z solution of household appliance production, our main product range include: Metal Stamping Machinery Drawing and Forming Machinery Polishing Machinery Surface Treatment Production Line Other Auxiliary Machinery Automatic Manipulator Mould

2023 06/15

- New Electric Kettle Welding Machine, Innovative Technology for Efficient Automated ProductionRecently, a well-known domestic electrical equipment manufacturer launched a brand new Electric Kettle Welding Machine (electric kettle welding machine), which realizes efficient and automated production through innovative technology, and has become the focus of attention of the electrical industry. It is understood that the Electric Kettle Welding Machine is equipped with advanced intelligent control system and machine vision technology, which realizes the fully automatic control of the production process of automatic feeding, positioning, welding and blanking of electric kettle blanks. Moreover, the machine can also automatically detect the welding quality, avoiding errors caused by manual detection, and improving production efficiency and quality. In addition, the Electric Kettle Welding Machine also uses high-precision pneumatic components and advanced mechanical structure design to ensure welding accuracy and stability. Moreover, the machine has a compact structure, simple operation, and a small footprint, saving manpower and space costs. According to the manufacturer, this Electric Kettle Welding Machine has been widely used in the production field of the electrical appliance industry and has been highly praised by users. Market experts also believe that the launch of this machine will further promote the improvement of production efficiency and quality in the electrical industry, and become one of the important symbols of automatic production in the industry. Foshan Youngmax machine co,.ltd focus on provide turn-key solution for new factory setting up.Below are our main products line with turn-key solution include :New factory planning, process feasibility analysis,Metal Stamping Machinery.Drawing And Forming Machinery.Polishing Machinery.Surface Treatment Production Line.Automatic Manipulator.Mould development ,machine installation, product testing, staff training and maintenance, technical support, etc.

2023 06/12

- Will the Machines eliminate workers in the future?With the rapid development of technology, machines become more intellectualized. 1. Speed: Machines can process information and perform tasks much faster than humans. 2. Accuracy: Machines are less prone to errors and can perform repetitive tasks with high precision. 3. Consistency: Machines can perform the same task repeatedly without getting tired or making mistakes. 4. Capacity: Machines can store and process vast amounts of data and information. 5. Efficiency: Machines can perform complex tasks with minimal waste of time, resources, and energy. 6. Safety: Machines can perform dangerous tasks that are too risky for humans, such as working in hazardous environments or handling toxic materials. 7. Cost-effectiveness: Machines can perform tasks at a lower cost than humans, especially in industries that require a lot of manual labor. However, human still the one in the main control--the adjustment of the program, daily maintenance of the machines, etc It is still a long way to go, why not try to accept? Youngmax machine focus on providing A-Z solution of household appliance production, our main product range include: Metal Stamping Machinery Drawing and Forming Machinery Polishing Machinery Surface Treatment Production Line Other Auxiliary Machinery Automatic Manipulator Mould

2023 06/09

Email to this supplier